Useful Information

Product Quality

The mechanical strength test determines whether the glasses are classified into protection class S, F or B. The mechanical strength is classified equally for the frames and lenses. If the frames and lenses have different strengths, the entire pair of glasses only receives the lower certification (S) (test method: ball drop test & bullet test).

Possible hazards in the workplace

Safety glasses for spectacle wearers combine frames and lenses. Therefore, both the frames and the different lens variants must be tested and certified separately. Below we give you an overview of the individual test procedures to which both frames and lenses are subjected. This illustrates the high quality standards that are placed on our safety glasses.

Private glasses are not safety glasses!

Private glasses are not suitable as safety glasses because they do not provide sufficient protection against the dangers at work. In some companies, however, employees often use old and discarded private glasses, which are usually still fitted with lenses of the wrong strength. Even during normal and routine work processes there is a risk that metal shavings, wood splinters or liquids, for example, could get into the eyes. Permanent visual impairment or even complete blindness can be the result of injuries. The employer must therefore provide suitable eye protection. The trade association also expressly recommends the use of corrective safety glasses, however, as only these optimally combine protective function and corrective effect.

Ball drop test – increased strength (S)

The object to be tested must withstand the impact of a steel ball with a nominal diameter of 22mm and a weight of at least 43g from a distance of 1.30m. The speed of the steel ball is approximately 5.1 m/s. After the test, the material is examined for fractures or deformations.

Ball impact test – low energy impact (F) and medium energy impact (B)

The tested spectacle frame or lens must withstand the impact of a steel ball with a nominal diameter of 6mm and a weight of at least 0.86g. In the test procedure for the lower energy “F”, the speed of the steel ball is ≥ 45 m/s. In the test procedure for the medium energy “B”, the speed of the steel ball is ≥ 120 m/s. After the test, the material is examined for fractures or deformations.

Flammability

The end of a steel rod is heated to a temperature of ≥ 650°C. The heated surface is pressed onto the tested spectacle frame or lens. The material must then neither ignite nor continue to smolder within 5 seconds.

Resistance to elevated temperatures/aging

The tested spectacles are placed in an oven/heating cabinet in the normal position for use for 60 minutes at a temperature of 55°C. They are then checked for deformation, aging and optical changes.

Corrosion resistance

The spectacle frame to be tested is placed in a boiling sodium chloride solution for 15 minutes. Then in a sodium chloride solution at room temperature for a further 15 minutes. This is rinsed and dried for a visual inspection. During the assessment, the surfaces of all metal parts must be smooth and free of corrosion.

Field of view

The spectacle frame must have a sufficient field of view. For this purpose, a laser is used to simulate specific viewing directions on a standardized test head. The frame is only approved if the defined minimum field of view is maintained.

Side protection/cover area

The side protection on the spectacle frame must not restrict the wearer’s field of view too much, similar to the field of view measurement for frames. In addition, it must cover the side of the eye well, so that no foreign bodies can hit the eye from the side.

Resistance to damage from small particles

Sand trickle test: 3kg of natural quartz sand of a defined grain class is sprinkled through a downpipe (diameter 12cm, height 165cm) from a distance of 170cm through a sieve onto the lens. The lens is then tested using an optical scattered light test (see scattered light).

Aging resistance to UV radiation

The tested lens is exposed to the radiation of a strong UV lamp for a period of 50 hours. This simulates the storage and/or use of protective glasses with lenses in sunlight over a period of approx. 2 years. It is then measured whether transmission and scattered light meet the specified standards.

UV protection filter

Prolonged and unprotected UV exposure poses the risk of serious eye damage, such as retinal injuries and lens clouding. Here it is examined and measured whether the required UV protection of the lenses is guaranteed.

Scattered light

Scattered light is an optical effect that makes a perceived image appear blurred and weakens the contrast. A clearly defined laser beam is passed through the lens at a specified angle. With the help of a radiation receiver it is checked whether a possible deviation and scattering of the luminous flux is within the tolerance.

Light transmission level

The light transmission level of a lens is determined with a spectrophotometer and defines the light transmittance of a lens. Lenses that are intended exclusively for protecting the eyes against mechanical or chemical hazards must have a higher light transmittance than 74.4%.

Signal light detection

The limited perception of signal colors such as red, yellow, green and blue represents a significant risk potential. By measuring the corresponding light wavelengths, the extent to which signal colors are distorted is checked.

Refractive power / spherical and astigmatic effect

The lens is checked using a lensmeter based on defined correction values and must be within specified tolerances. Only then does it receive the best possible and required optical class 1.

Material and surface quality

The lens is examined for defects that could affect the optical quality. Such defects can be, for example, scratches, inclusions, bubbles or clouding.

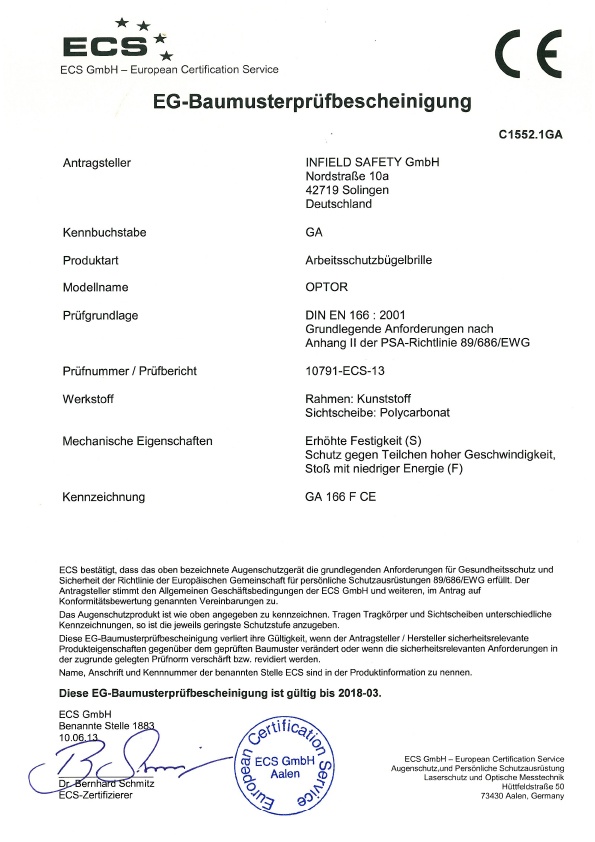

The certificate

After successfully completing the test procedure, the safety glasses are approved to be used as safety glasses. For the corresponding test result, the certificate is issued in the form of a type certificate for each safety glasses model. The labellings specified on the type certificates must be engraved on both the lenses and the frame.

Only glasses with a corresponding labelling may be used as safety glasses and guarantee sufficient protection against potential hazards at work.

Labellings according to DIN EN 166

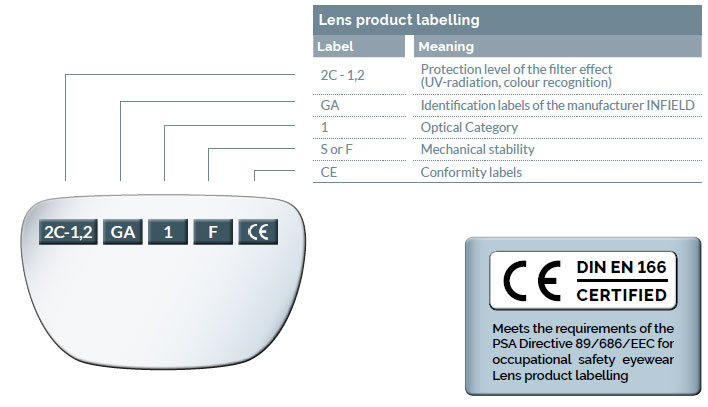

Labellings of the lenses

The engraving on the upper edge of the lens contains only the most necessary information so that the field of vision is not restricted.

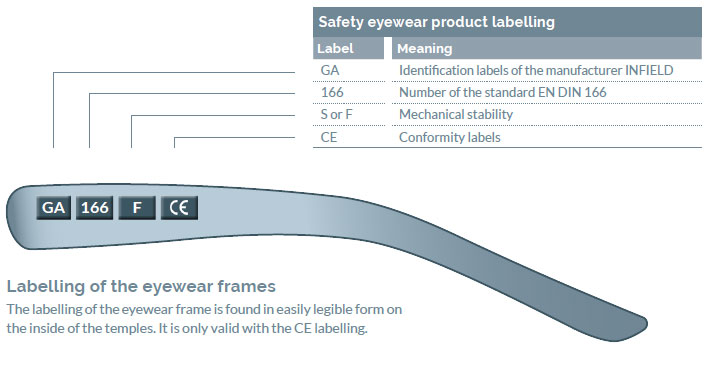

Labellings of the glasses frames

The labelling of the glasses frame can be found clearly on the inside of the temple. It is only valid with the CE labelling.

Materials

Polycarbonate (PC)

INFIELD polycarbonate lenses are characterized by their extremely high mechanical strength and are therefore ideally suited as safety lenses for protective eyewear. PC lenses are very light compared to mineral glass lenses and do not cause sparks on the surface of the lenses. However, protective lenses made of PC are less resistant to scratches and therefore should be used with a scratch-resistant coating (HC). In addition, a hard coat improves the protection against chemical influences.

Special material characteristics: PC was originally developed for applications within the aeronautics industry and has since been utilised, due to it’s properties, as an ideal material for safety eyewear. Basically PC is a very soft and tough plastic that is characterised by its high strength. Energy caused by the impact of foreign bodies is absorbed by the material upon contact which leads to a higher impact resistance compared to other plastic materials.

Acetat (AC)

Acetate (cellulose propionate) is a thermoplastic consisting of, among other things, natural cotton. INFIELD acetate lenses are very form-flexible and therefore ideal for the usage in full-view safety goggles. A special coating prevents the lens from fogging and ensures longer lasting clear vision.

Special material characteristics: Acetate is very resistant to most chemical substances used in medicine and industry. Thus safety goggles with acetate lenses are perfect to protect when working with acids and alkalis, bleachers and cleansers, oils, brines as well as hydrocarbons.

Hard Glass (mineral glass)

Protective lenses made of mineral glass are very resistant against scratches and are also characterised by high resistance to chemicals. Mineral glass is suitable for very dusty and sandy working environments. The high scratch resistance makes it easy to clean.

Trivex

Trivex as material for spectacle lenses is an innovative further development in the field of plastic spectacle lenses. It is ideally suited for work safety due to its material characteristics. TRIVEX offers the comfort of being particularly low weight whilst being extremely break-proof due to its very high mechanical impact and tensile strength. Regardless of the spectacle lens thickness, TRIVEX ensures an excellent optical quality providing clear and sharp vision without visual interference. Furthermore, spectacle lenses made of TRIVEX protect against harmful UV-radiation and are resistant to many chemicals and solvents.

Coating

ProCoat

Perfect protection in all work situations

Our coatings are based on many years’ experience developing products for personal protection equipment (PPE). Our problem-specific solutions for very hazardous situation.

CLEAR HC – super scratch resistant

This special lacquer coating greatly enhances scratch-resistance on both surfaces of the lens In addition, the hard coat-ing improves the protection against chemical influences.

Areas of application: This coating is suitable for environments in which the safety spectacles need frequent cleaning. Dust and grit are just as easily removed as thin and viscous fluids.

| Coating(s): | Hard Coating | ||

|---|---|---|---|

| HC | Designation (abbr.): | HC |

CLEAR AF AS – anti-fog, scratch-resistant, antistatic

This coating makes safety lens scratch-resistant, anti-fog and anti-static on both the inner and outer surfaces. In particular, a combination of anti-fog and anti-static effects ensures clear vision for long periods. The lens surfaces remain dirt-free for longer and are more easily cleaned.

Areas of application: This coating is suitable for work in constantly changing temperatures, when perspiration build-up is a problem and/or for activities in moist, warm and dusty environments.

| Coating(s): | Anti Fog | Anti Statik | ||

|---|---|---|---|---|

| CLEAR AF AS | Designation (abbreviation): | AF | AS |

CLEAR AFP – super scratch-resistant, super condensation-free, antistatic

The perfect coating combination of INFIELD´s CLEAR HC and CLEAR AF AS with enhanced scratch-resistance and anti-fog on both the inner and outer surfaces of the glasses. This improved anti-fog effect ensures that the glasses are fog resistant even with extreme temperature fluctuations. The enhanced scratch-resistance provides greater protection from external effects.

Areas of application: This coating is suitable for environments in which the safety spectacles need to be cleaned frequently. Dust and grit are just as easily removed as thin and viscous fluids. Additionally, this coating is suitable for work in constantly changing temperatures, when perspiration build-up is a problem and/or for activities in moist, warm and dusty environments.

| Coating(s): | Hard Coating | Anti Fog | Anti Statik | ||

|---|---|---|---|---|---|

| CLEAR AFP | Designation (abbreviation): | HC | AF | AS |

CLEAR SAR – super anti-reflection

CLEAR SAR eliminates practically all distracting reflections. Particularly in working environments where safety spectacles have to be worn under bright artificial light, this super anti-reflection effect helps prevent tired eyes and supports concentration. With lenses without anti-reflective coating, 4% of the light information is reflected on the front and back. Accordingly, the eye receives only 92% image information. The CLEAR SAR coating reduces these interference reflections almost completely so that the eye receives 100% image information. This coating thus contributes to fatigue-free vision and makes working under artificial light much easier. With their additional hard layer, safety lenses with CLEAR SAR are also scratch and chemical-resistant.

Areas of application: This type of coating is particularly suitable for production areas where safety goggles are mandatory and in industrial environments with strong artificial light, eg assembly halls.

| Coating(s): | Super Anti Reflex | Hard Coating | ||

|---|---|---|---|---|

| CLEAR SAR | Description(s) (abbr.) | SAR | HC |

Lens Tints

Below you will find an overview of the different tints of the protective lenses for face protection glasses.

| CLEAR colourless | |||

|---|---|---|---|

| Available for lens material(s) | Polycarbonate, acetate | CLEAR colourless lenses are available in a number of designs with a range of coatings. |  |

| Standard | EN 166, EN 170 | ||

| UV-protection | UV 385 | ||

| Optical quality | class 1 | ||

| Transmission | 91 to 96% | ||

| Lens designation | 2C-1,2 | ||

| CONTRAST amber | |||

|---|---|---|---|

| Available for lens material(s) | Polycarbonate | Enhanced contrast for work in low light conditions. |  |

| Standard | EN 166, EN 170 | ||

| UV protection | UV 385 | ||

| Optical quality | class 1 | ||

| Transmission | 89% | ||

| Lens designation | 2 - 1,2 | ||

| CONTRAST orange | |||

|---|---|---|---|

| Available for lens material(s) | Polycarbonate | Enhanced contrast + anti-dazzle protection for work in low light conditions in the open air. |  |

| Standard | EN 166, EN 170 | ||

| UV protection | UV 385 | ||

| Optical quality | class 1 | ||

| Transmission | 47% | ||

| Lens designation | 2 - 1,7 | ||

| SUN Grey | |||

|---|---|---|---|

| Available for lens material(s) | Polycarbonate | Anti-glare protection in sunlight |  |

| Standard | EN 166, EN 170, EN 172 | ||

| UV protection | UV 385 | ||

| Optical quality | class 1 | ||

| Transmission | 23% | ||

| Lens designation | 5-2,5 | ||

| ProCoat MIRROR blue | |||

|---|---|---|---|

| Available for lens material(s) | Polycarbonate | Protection from extreme natural and artificial glare and dissipation of radiated heat. |  |

| Standard | EN 166, EN 170, EN 172 | ||

| UV protection | UV 385 | ||

| Optical quality | class 1 | ||

| Transmission | 20% | ||

| Lens designation | 5-2,5 | ||

| ProCoat MIRROR silver | |||

|---|---|---|---|

| Available for lens material(s) | Polycarbonate | Protection from extreme natural and artificial glare and dissipation of radiated heat. |  |

| Standard | EN 166, EN 170, EN 172 | ||

| UV protection | UV 385 | ||

| Optical quality | class 1 | ||

| Transmission | 20% | ||

| Lens designation | 5-2,5 | ||

| POLARIZATION | |||

|---|---|---|---|

| Available for disc material | Polycarbonate | Polarized safety glasses are ideal for activities on and around water as well as in bright outdoor areas. They ensure increased concentration and fatigue-free working with increased contrast and unadulterated color representation. |  |

| Norm | EN 166, EN 172 | ||

| UV protection | UV 385 | ||

| Optical quality | Class 1 | ||

| Transmission | 10% | ||

| Lens marking | 5-3,1 | ||

| ProCoat MIRROR light Gold | |||

|---|---|---|---|

| Available for lens material(s) | Polycarbonate | Protection from glare in varying light conditions |  |

| Standard | EN 166, EN 170, EN 172 | ||

| UV protection | UV 385 | ||

| Optical quality | class 1 | ||

| Transmission | 53% | ||

| Lens designation | 5-1,7 | ||

| ProCoat MIRROR red/brown | |||

|---|---|---|---|

| Available for lens material(s) | Polycarbonate | Protection from glare during sport and leisure activities |  |

| Standard | EN 166, EN 170, EN 172 | ||

| UV protection | UV 400 | ||

| Optical quality | class 1 | ||

| Transmission | 12% | ||

| Lens designation | 2-3 | ||

| ProCoat UV 400 | |||

|---|---|---|---|

| Available for lens material(s) | Polycarbonate | Protection from high-level UV radiation and Blue-light stress, e. g. medical environments. |  |

| Standard | EN 166, EN 170, EN 172 | ||

| UV protection | UV 400 | ||

| Optical quality | class 1 | ||

| Transmission | 44% | ||

| Lens designation | 2-1,7 | ||

| INFRARED | |||

|---|---|---|---|

| Available for lens material(s) | Polycarbonate | Protection from Infrared radiation emitted from kilns and furnaces, for example. |  |

| Standard | EN 166, EN 170, EN 171 | ||

| UV protection | UV 400 | ||

| Optical quality | class 1 | ||

| Transmission | 55% | ||

| Lens designation | 4-1,7 | ||

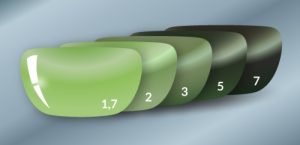

| WELDING | |||

|---|---|---|---|

| Available for lens material(s) | Polycarbonate | A range of safety lenses for a variety of applications in welding operations. From welding to flame-cutting, 5 levels of welder protection are available. |  |

| Standard | EN 166, EN 169 | ||

| UV protection | UV 400 | ||

| Optical quality | class 1 | ||

| Transmission | 1-43% | ||

| Lens designation | 1,7/2/3/4/5/6 | ||

| ProCoat PHOTOCHROMIC | |||

|---|---|---|---|

| Available for lens material(s) | Polycarbonate | Safety lenses with a self-activating filter, which quickly quickly Reduces glare from solar radiation. The variable auto-tint function makes safety spectacles with this coating suitable for frequent and rapidly changing light conditions. |  |

| Standard | EN 166, EN 172 | ||

| UV protection | UV 385 | ||

| Optical quality | class 1 | ||

| Transmission | 12-82% | ||

| Lens designation | 5-1,1 | ||

Labelling

Labellings according to DIN EN 166

Protection level of filter effect / tint

Detailed information on INFIELD protective lens technology can be found on pages 8-9 in our protective eyewear catalogue

Optical Class

There are 3 different optical classes to assess the quality of the lenses. All of our protective lenses have optical class 1, which corresponds to the highest quality.

The EU directive EN 166 describes the labeling requirement for safety glasses. All INFIELD frames and protective lenses are labeled accordingly.

The positioning of the label is not specified. It is important that the labeling of the protective lenses does not restrict the wearer’s field of vision.

Mechanical strength coding

| Code | Meaning | strength |

|---|---|

| none | minimum strength |

| S | enhanced strength |

| F | low-energy impact (45 m/s) |

| B | medium-energy impact (120 m/s) |

| A | high-energy impact (190 m/s) |

| T | protection against high-speed particles at extreme temperatures |

Field of application coding

| Code | Meaning | field of application |

|---|---|

| none | standard application |

| 3 | liquids |

| 4 | grit |

| 5 | gases and dust |

| 8 | fault arc (safety face visor) |

| 9 | molten metal and hot solids |